YR heat shrinkable sleeve

Product consultation telephone: 13926000236

Product Details

Features:

Features:

Beautiful appearance, high fit,

flame retardant, insulation, provide mechanical protection and stress relief;

resistant to fuel oil, mineral oil and chemical solvents; the

inner wall is pre-coated with meltable glue to achieve waterproof and moisture-proof effect, with

many types of materials and a wide temperature range;

Application use:

Shaping, insulation protection and strain relief of cable terminal connections, openings and furcation connections.

Product Code:

Shape code: Z-straight, W-curved, TT, CY forked;

material code: -3 semi-rigid polyolefin, -4 soft polyolefin, -71 semi-rigid polyolefin, -12 fluororubber, -25 oil-resistant elastomer;

pre-applied glue code: -42 polyamide hot melt adhesive, -86 EVA hot melt adhesive;

1. Material code: -3 semi-rigid polyolefin, -4 soft polyolefin, -71 semi-rigid polyolefin , -12 fluororubber, -25 oil-resistant elastomer;

2. Pre-applied glue code: -42 polyamide hot melt adhesive, -86EVA hot melt adhesive;

Material properties:

|

material code |

material name |

temperature range |

Application Features |

|

-3 |

semi-rigid polyolefin |

-55℃~135℃ |

Cross-linked heat shrinkable, flame retardant, resistant to partial fluid immersion and chemical corrosion |

|

-4 |

Soft Polyolefin |

-55℃~135℃ |

Cross-linked heat shrinkable, flame retardant, resistant to partial fluid immersion and chemical corrosion |

|

-71 |

Semi-rigid modified polyolefin |

-55℃~135℃ |

Cross-linked heat shrinkable, flame retardant, long-term resistance to fluid immersion and chemical corrosion |

|

-25 |

Oil Resistant Elastomer |

-55℃~150℃ |

Cross-linked heat shrinkable, wear-resistant, long-term resistance to fluid immersion and chemical corrosion at 150°C |

|

-12 |

Soft Viton |

-55℃~200℃ |

Cross-linked heat shrinkable, wear-resistant, long-term resistance to fluid immersion and chemical corrosion at 200°C |

Product Size:

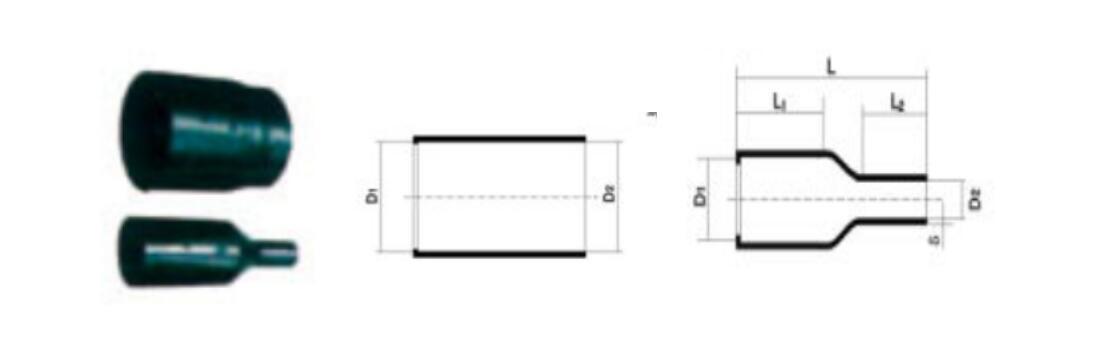

1. Shrinkable shrink sleeve (unit: mm)

|

product code |

Minimum size before shrinking |

Maximum size after shrinking |

||||||

|

D1 |

D2 |

D1 |

D2 |

L±10% |

L1±10% |

L2±10% |

δ±20% |

|

|

Z021 |

11.0 |

11.0 |

5.0 |

2.0 |

40 |

twenty one |

12 |

1.5 |

|

Z121 |

18.0 |

18.0 |

7.0 |

3.0 |

43 |

twenty one |

14 |

1.5 |

|

Z1212 |

18.0 |

18.0 |

7.0 |

4.0 |

50 |

18 |

28 |

1.8 |

|

Z221 |

25.0 |

25.0 |

9.5 |

4.0 |

50 |

twenty three |

16 |

1.6 |

|

Z2212 |

25.0 |

25.0 |

11.0 |

7.0 |

82 |

25 |

56 |

1.8 |

|

Z321 |

30.0 |

30.0 |

13.0 |

6.0 |

56 |

25 |

20 |

1.8 |

|

Z421 |

34.0 |

34.0 |

16.8 |

7.0 |

60 |

26 |

20 |

2.0 |

|

Z4212 |

34.0 |

34.0 |

16.8 |

7.0 |

70 |

36 |

20 |

2.0 |

|

Z521 |

40.0 |

40.0 |

20.0 |

8.4 |

68 |

30 |

20 |

2.0 |

|

Z5212 |

40.0 |

40.0 |

20.0 |

8.4 |

85 |

48 |

20 |

2.0 |

|

Z621 |

46.0 |

46.0 |

26.0 |

9.0 |

70 |

30 |

20 |

2.3 |

|

Z6212 |

46.0 |

46.0 |

26.0 |

9.0 |

85 |

45 |

20 |

2.3 |

|

Z721 |

60.0 |

60.0 |

30.0 |

14.0 |

70 |

30 |

20 |

2.6 |

|

Z821 |

75.0 |

75.0 |

40.0 |

18.0 |

70 |

30 |

20 |

2.6 |

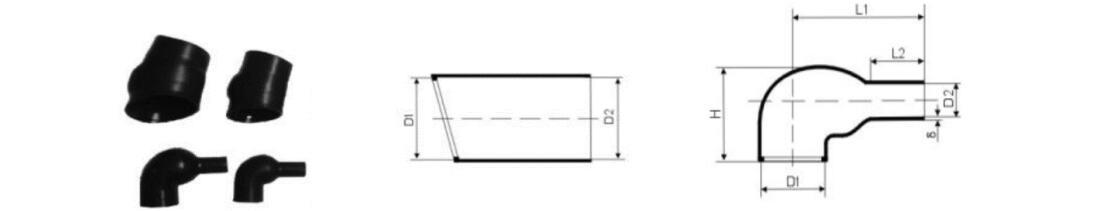

2. Heat-shrinkable bending sleeve (unit: mm)

|

product code |

Minimum size before shrinking |

Maximum size after shrinking |

||||||

|

D1 |

D2 |

D1 |

D2 |

H±10% |

L1±10% |

L2±10% |

δ±20% |

|

|

W1 |

18.0 |

18.0 |

7.0 |

3.0 |

20.0 |

21.0 |

10.0 |

1.5 |

|

W2 |

25.0 |

25.0 |

9.5 |

4.0 |

26.0 |

32.0 |

15.0 |

1.6 |

|

W3 |

30.0 |

30.0 |

13.0 |

6.0 |

28.4 |

34.0 |

16.0 |

1.6 |

|

W4 |

34.0 |

34.0 |

16.8 |

7.0 |

34.0 |

42.0 |

18.0 |

2.0 |

|

W5 |

40.0 |

40.0 |

20.0 |

8.5 |

38.0 |

47.0 |

20.0 |

2.0 |

|

W6 |

46.0 |

46.0 |

26.0 |

9.0 |

46.2 |

56.0 |

20.0 |

2.3 |

|

W7 |

60.0 |

60.0 |

30.0 |

14.0 |

54.0 |

62.0 |

21.0 |

2.6 |

|

W8 |

75.0 |

75.0 |

40.0 |

18.0 |

64.0 |

79.0 |

25.0 |

2.6 |

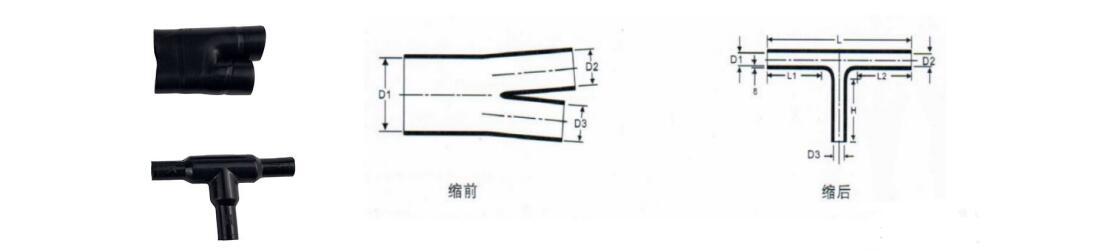

3. T-shaped heat shrinkable sleeve (unit: mm)

|

product code |

Minimum size before shrinking |

Maximum size after shrinking |

|||||

|

D1 |

D2/D3 |

D1 |

D2/D3 |

L±10% |

L1/L2/H±10% |

δ±20% |

|

|

T14933 |

19.8 |

13.2 |

6.6 |

6.6 |

80.8 |

25.4 |

1.02 |

|

T24933 |

34.3 |

22.9 |

11.4 |

11.4 |

120.4 |

41.1 |

1.27 |

|

T34933 |

60.2 |

40.1 |

20.1 |

20.1 |

175.4 |

63.5 |

1.52 |

|

T44933 |

83.3 |

54.9 |

33.3 |

33.3 |

242.3 |

83.9 |

1.78 |

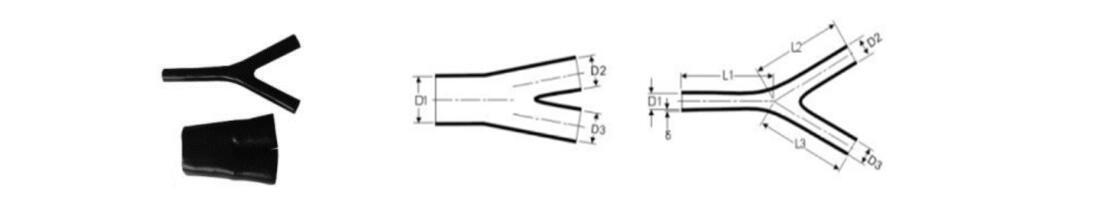

4. Y-type bifurcated heat-shrinkable sleeve (unit: mm)

|

product code |

Minimum size before shrinking |

Maximum size after shrinking |

||||

|

D1 |

D2/D3 |

D1 |

D2/D3 |

L1/L2/L3±10% |

δ±20% |

|

|

C1383 |

19.8 |

13.2 |

6.6 |

6.6 |

40.6 |

1.0 |

|

C2383 |

34.3 |

22.9 |

11.4 |

11.4 |

63.0 |

1.3 |

|

C3383 |

60.2 |

40.1 |

20.1 |

20.1 |

94.7 |

1.5 |

|

C4383 |

83.3 |

54.9 |

33.3 |

33.3 |

133.9 |

1.8 |

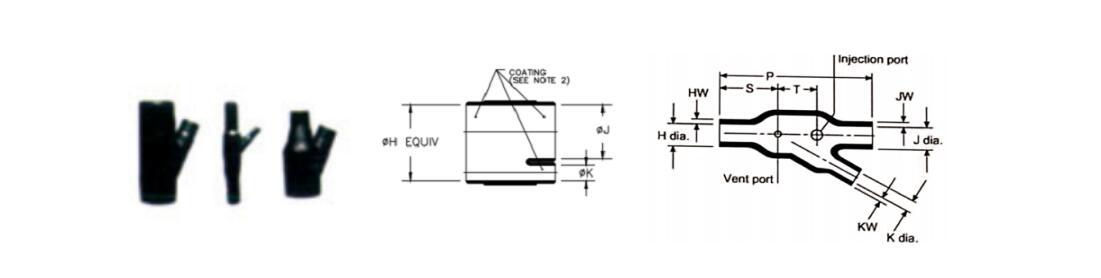

5. Y-shaped bifurcated 30° heat shrinkable sleeve (unit: mm)

|

product code |

Minimum size before shrinking |

Maximum size after shrinking |

||||||||||

|

H |

J |

K |

H |

J |

K |

P±10% |

S±10% |

T±10% |

HW/JW ±20% |

KW ±20% |

||

|

C138/30 |

30.5 |

30.5 |

20.3 |

20.3 |

15.7 |

10.7 |

82.6 |

31.8 |

21.1 |

2.54 |

1.78 |

|

|

C238/30 |

35.6 |

35.6 |

15.2 |

15.2 |

18.3 |

8.6 |

63.5 |

19.1 |

22.4 |

2.54 |

1.52 |

|

|

C338/30 |

35.6 |

35.6 |

10.2 |

10.2 |

18.8 |

5.3 |

61.0 |

19.1 |

21.3 |

2.79 |

1.52 |

|

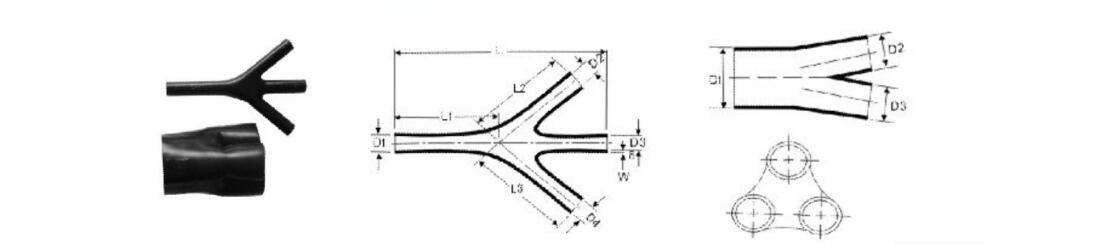

6. Y-shaped three-prong mold shrink sleeve (unit: mm)

|

product code |

Minimum size before shrinking |

Maximum size after shrinking |

|||||

|

D1 |

D2/D3/D4 |

D1 |

D2/D3/D4 |

L±10% |

L1/L2/L3±10% |

W±20% |

|

|

C14333 |

19.8 |

13.2 |

6.6 |

6.6 |

86.0 |

40.6 |

1.0 |

|

C24333 |

34.3 |

22.9 |

11.4 |

11.4 |

136.0 |

63.0 |

1.3 |

|

C34333 |

60.2 |

36.1 |

20.1 |

20.1 |

208.0 |

94.7 |

1.5 |

|

C44333 |

83.3 |

54.9 |

33.3 |

33.3 |

295.0 |

133.9 |

1.8 |

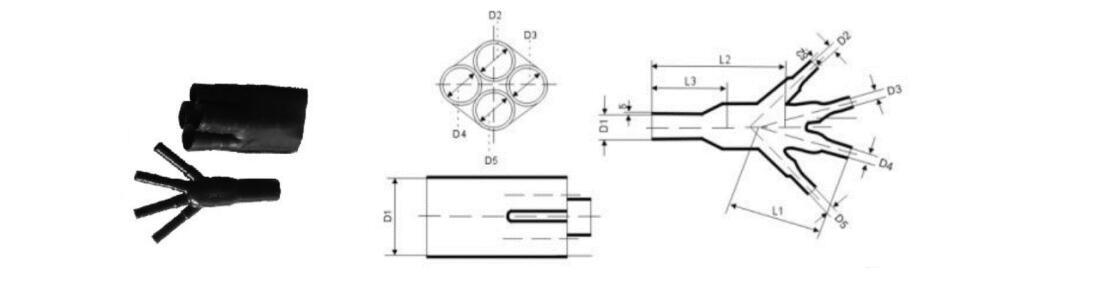

7. Y-type four-branch heat shrinkable sleeve (unit: mm)

|

product code |

Minimum size before shrinking |

Maximum size after shrinking |

|||||||

|

D1 |

D2/D3/ D4/D5 |

D1 |

D2/D3/ D4/D5 |

L1 |

L2 |

L3 |

δ1±20% |

δ2±20% |

|

|

C15333 |

13.2 |

6.6 |

6.9 |

3.4 |

24.1 |

43.2 |

18.0 |

1.52 |

1.02 |

|

C25333 |

19.3 |

9.4 |

9.7 |

5.3 |

35.6 |

43.2 |

23.1 |

1.78 |

1.02 |

|

C34333 |

19.3 |

13.2 |

9.7 |

6.9 |

49.3 |

50.5 |

25.4 |

1.78 |

1.52 |

|

C44333 |

26.9 |

13.2 |

13.0 |

6.9 |

49.3 |

65.8 |

33.5 |

2.54 |

1.52 |

|

C55333 |

38.6 |

19.3 |

18.5 |

9.7 |

71.9 |

95.3 |

46.5 |

3.05 |

1.78 |

|

C65333 |

55.6 |

26.9 |

26.7 |

13.0 |

101.6 |

135.1 |

65.5 |

4.57 |

2.54 |

heat shrink tubing

About Chuantuo

Product Display

Industry Application

Technical Support

Follow us

Guangzhou Chuantuo Electronic Technology Co., Ltd.

Address: No. 10, Yuehui 1st Street, Yongning Street, Zengcheng District, Guangzhou

Telephone:020-89285609 / 18902261386

Cell Phone:13926000236(Wechat same number)

QQ:549717796

Mail:derek79@126.com / sales@ctdzkj.com